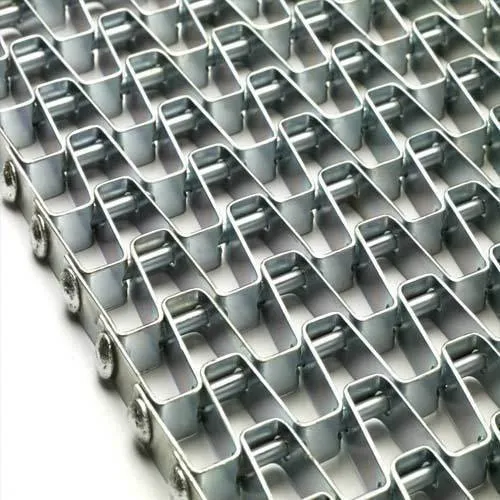

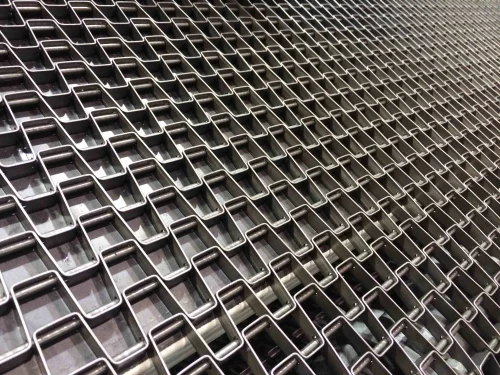

Honeycomb conveyor belt, also called flat wire conveyor belt. The honeycomb belt is constructed of cross rods and a flat metal strip.

At the sides of the belt the cross roads have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinged edge.

There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights. The flat wires are arranged in the form of lattice and jointed with the straight round rods. The material of flat wire belt are commonly high carbon steel, (G.I.) galvanized steel, SS304, SS304l, stainless steel and other materials.

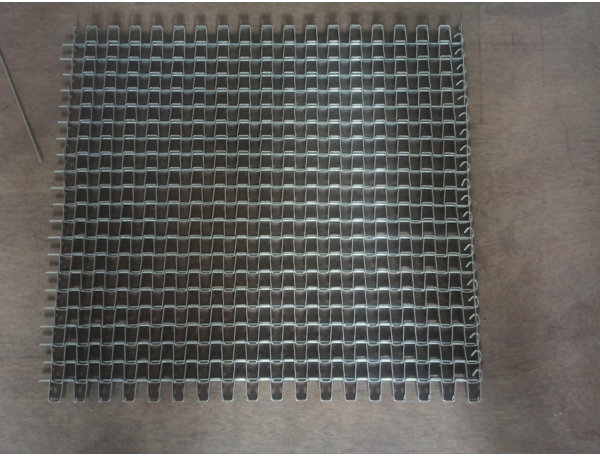

Honeycomb conveyor belt is a perfect products with both durability and suitable open area. It is temperature resistance, which is popular in the baking conveying applications. The flat surface of honeycomb conveyor belt supplies stable conveying during using. Honeycomb belts are used in production processes with temperatures of -30ºC up to +400ºC in food and other industries.

Honeycomb conveyor belt Advantages:

• Twice the life of competitive belts

• Installation requires no special tools

• Positive driven for excellent belt tracking

• Up to 81% open area for excellent flow through

• Allows for tight transfers

• Available up to 150 inches wide

• High strength-to-weight ratio

• Welded button edge or clinched edge

• Flat carrying surface

• Easy to clean and to install

• Easily joined

• Strong edge reduces snagging or catching on conveyor protrusions